As part of a multi-disciplinary team of engineers and perceptual scientists, I was responsible for early stage research and development of soft robotic systems and components at Facebook Reality Labs. In my role I helped to grow and lead a team of engineers and scientists, ran relationships with vendors, and developed novel models, designs, manufacturing processes, and test systems.

Video courtesy of the Tech@Facebook Blog

Concept

Foundational Research / Theory of Operation / Identification of Critical Parameters

I was asked to take concepts demonstrated in the academic literature and develop them into subsystems that could be integrated into a mass-produced wearable consumer product. I did a deep dive into the literature to understand the field, identify promising prototypes, and synthesize a basic theory of operation for a diverse set of soft robotic concepts. As part of this work, I recreated prior published work to vet a novel manufacturing process and identify critical performance parameters.

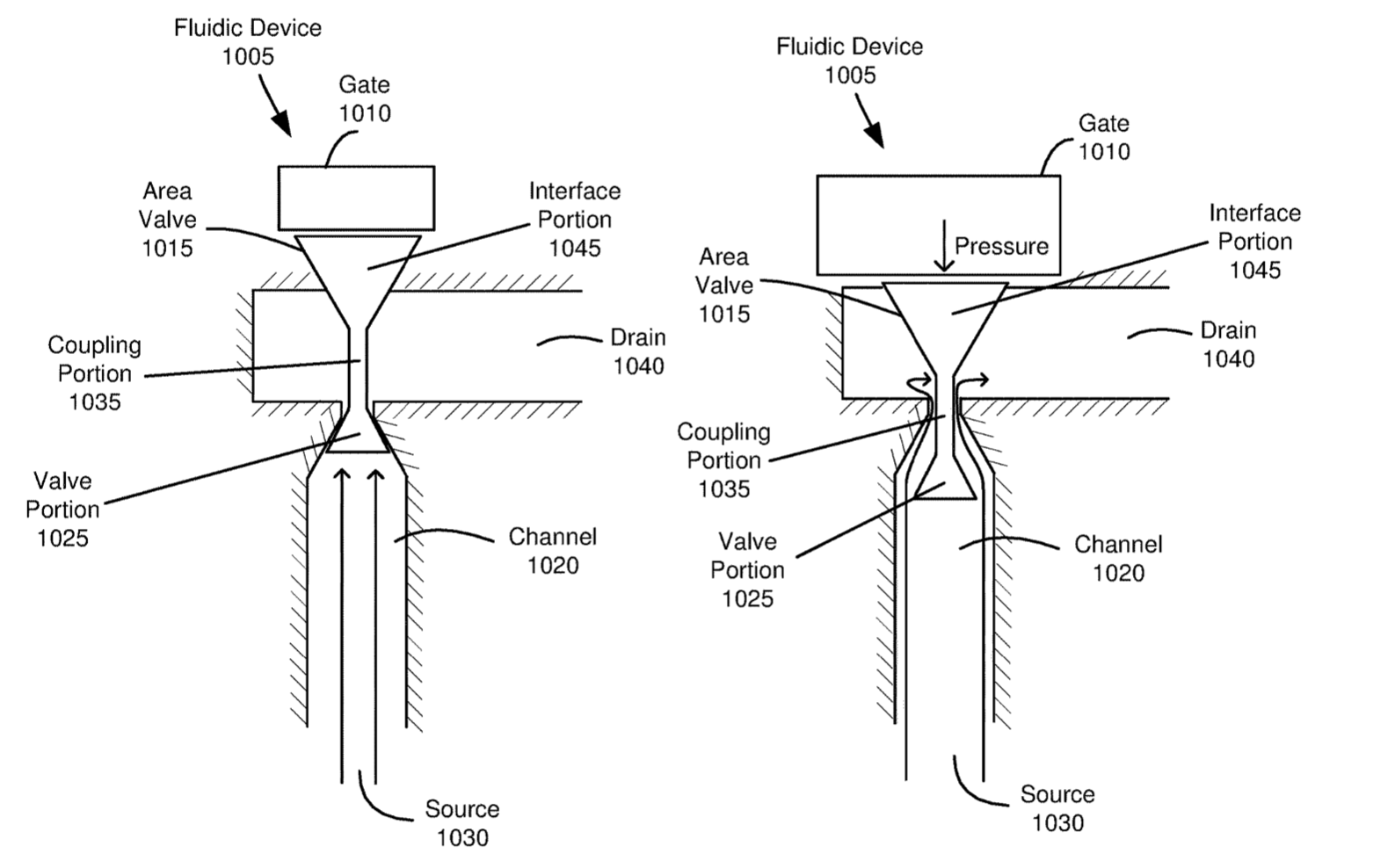

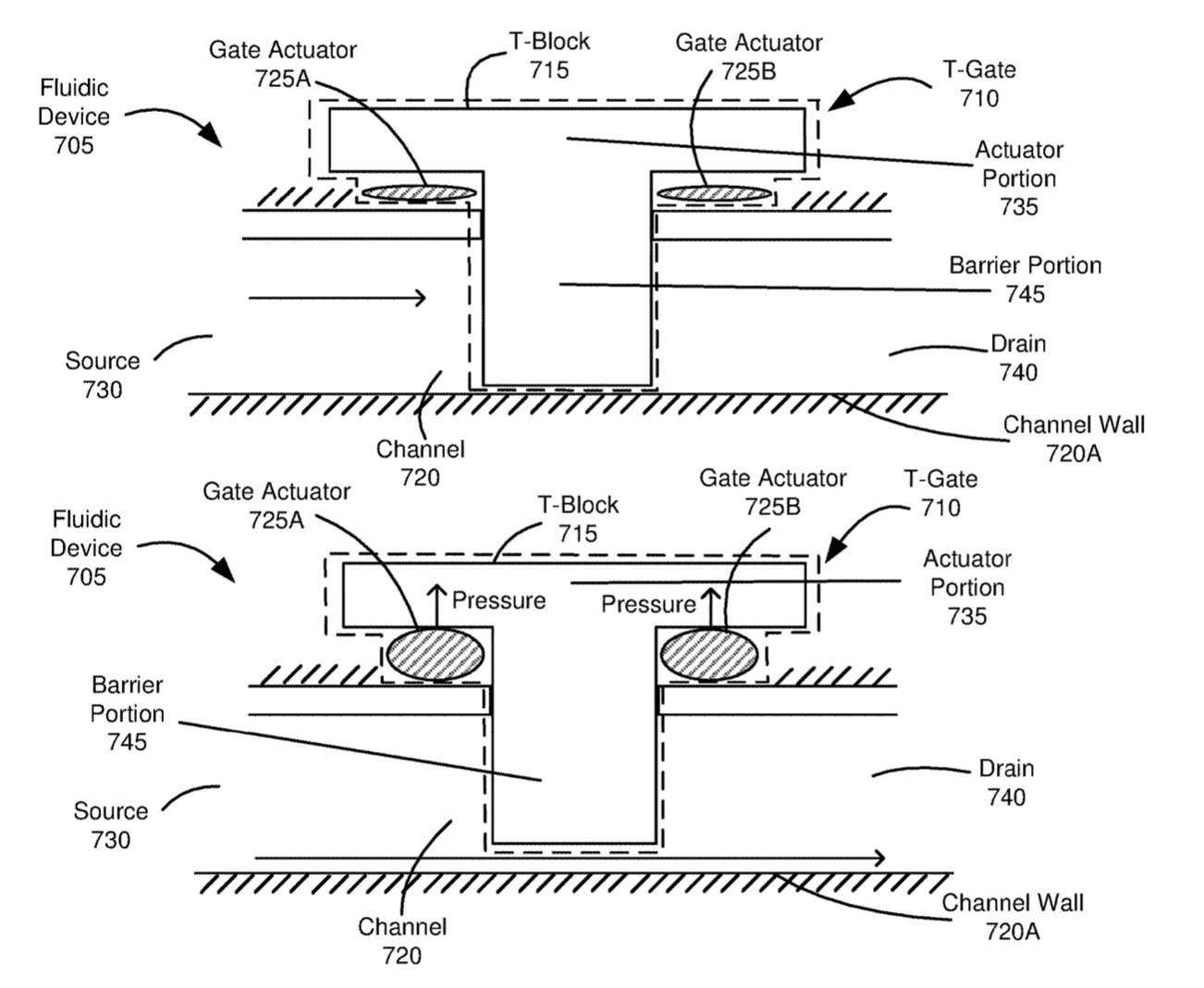

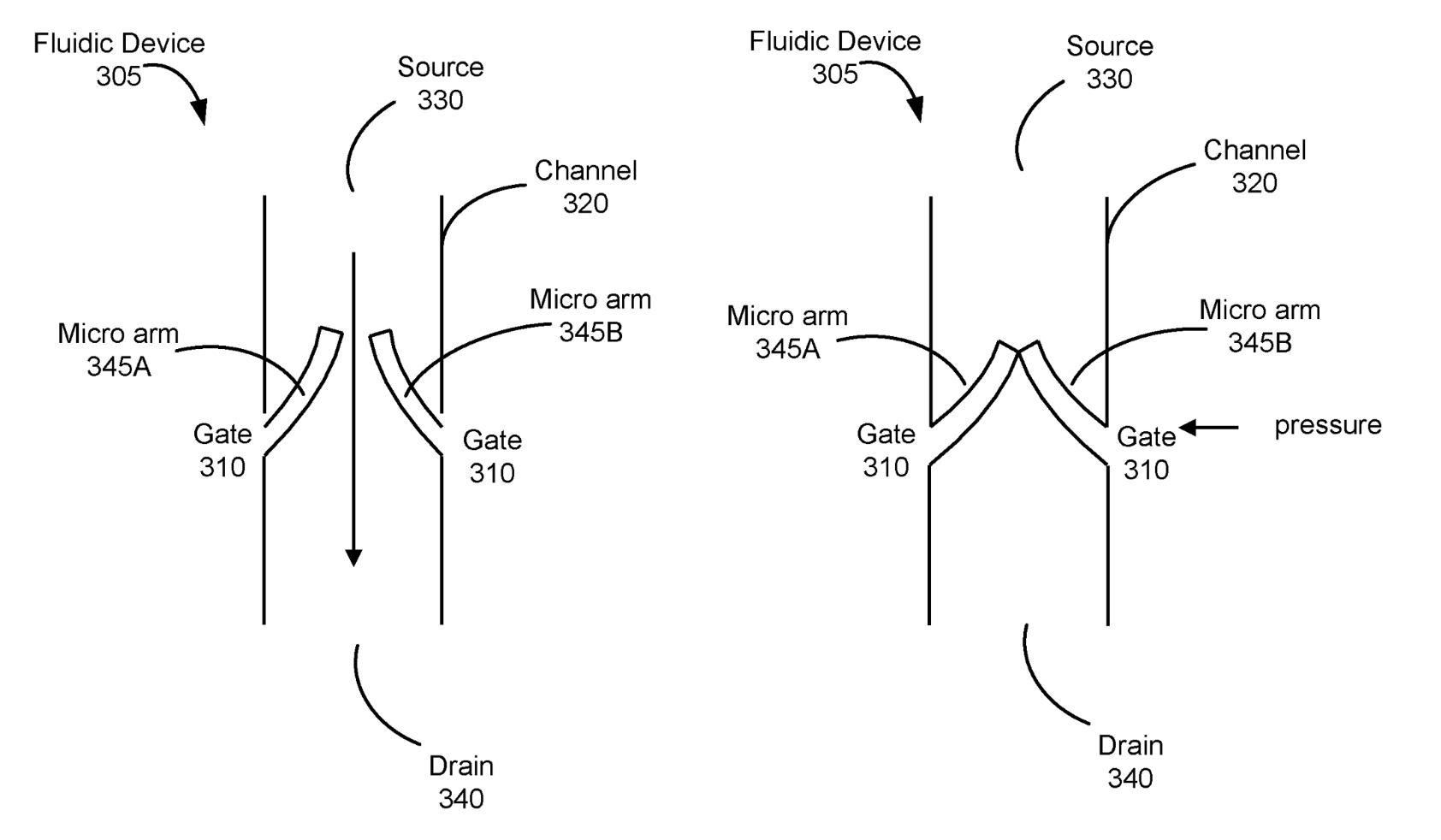

Fluid transistor designs patents I authored

Design

Brainstorming / Analytical Modeling / CAD Modeling / Rapid Prototyping

To generate new designs, I ran brainstorming sessions with the team and used analytical models to sort good ideas from bad. Several of these designs have now led to the patents shown above.

I proved (or disproved) the utility of these new designs using a variety of rapid prototyping processes including heat-welding, sewing, silicone molding, plasma bonding, lost wax casting, CNC machining, laser cutting, and 3D printing.

The quick prototypes provided insight into how the silicone and fabric devices would behave when pressurized, and I used them as the basis for simple analytical models. I used these analytical models to inform more sophisticated designs which were used for feasibility analysis and early integration testing. Several of these designs are captured in patents shown above.

Example test system, courtesy of Soft Robotics Toolkit

Testing

Test Design / Test System Development / Data Analysis

I led a team of engineers and research scientists as we created state-of-the-art test and measurement systems for microfluidics and soft robotics. As technical lead, I wrote architectures, defined test and metrology requirements, contributed to test design and drafting of standard operating procedures (SOPs), performed root-cause analysis, and wrote analysis scripts in MATLAB.

Simplified architecture for a haptic glove driven by a microfluidic controller

System Integration

Interfaces / System Energy Flows / Design Rules

In collaboration with technical leads for neighboring subsystems, I created subsystem architectures and defined interfaces to the rest of the system and helped work through problems in integration.

In close collaboration with another research scientist, I created new models to describe system-level energy flows, and used them to evaluate different system architectures, putting bounds on performance and elucidating trade-offs between size, weight, and output.

To aid in the construction of complex soft devices, I developed a set of design rules used to drive manufacturing development and ensure designs could be manufactured and integrated.

The work has resulted in 16 published patents thus far, 14 of which have been granted with 2 pending.